Ensuring quality in every test

Quality assurance is a priority for every business. Whether conducting functionality tests or verifying electrical connections, our custom-designed test platforms meet the challenge.

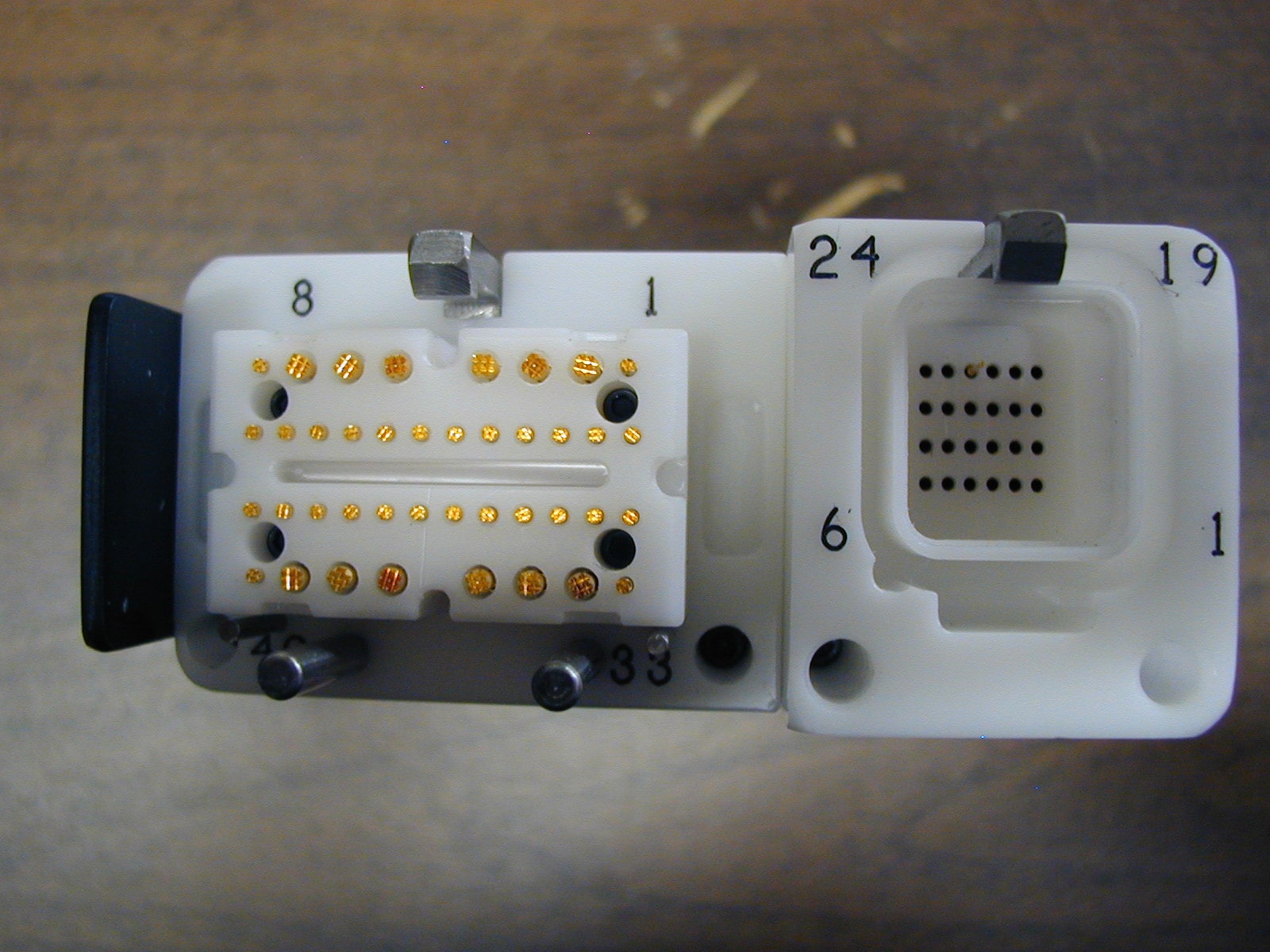

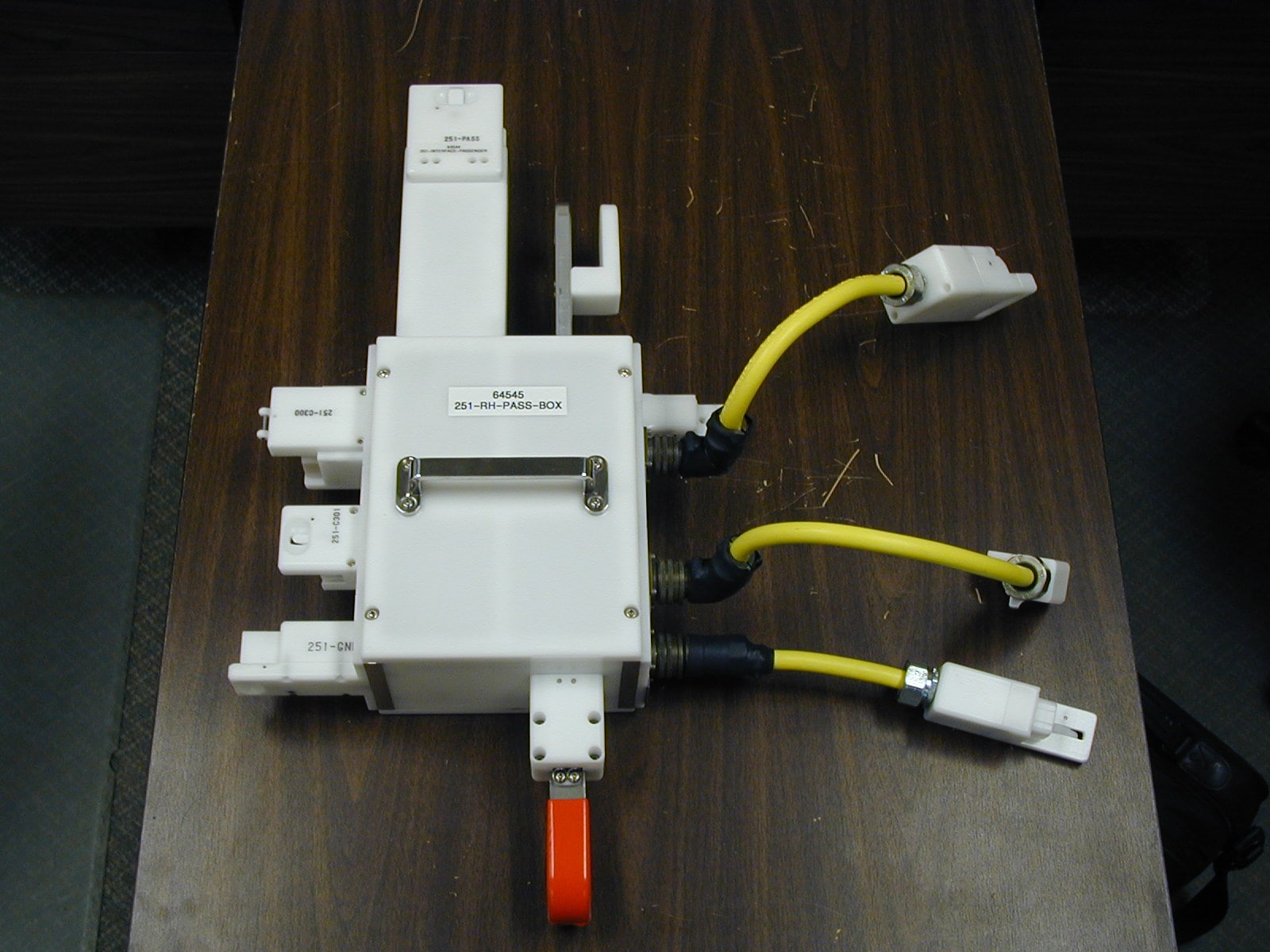

Each tester is created with your end product in mind. Platforms can feature operator interfaces ranging from simple indicator lights and small panel displays to full-scale displays. An industrial computer interacts with an I/O device on most test platforms to check continuity. This computer runs TSL test software (explained below). Combined with various communication protocols, this setup enables the required tests on electrical subassemblies, such as vehicle instrument panels.

Benefits of our specialized test platforms

Understanding the Test Sequence Language (TSL)

The Test Sequence Language (TSL) is a scripting language designed for writing sequenced test programs, commonly referred to as scripts. TSL scripts are straightforward to create, modify, and understand, making them accessible to engineers and plant electricians.

These scripts can be written using any ASCII text editor. Once written, scripts are processed, interpreted, and executed by the application. The TSL application comprises the test engine and, optionally, an I/O module operating on a computer platform equipped with the necessary I/O hardware. This setup enables the application to perform electrical, functional, operational, and diagnostic tests on circuits and modules, either individually or in combination.

Protocol support and customization capabilities

TSL supports a wide range of network protocols, including:

- SAE J2534-1 & J2534-2: Compliant with both specifications.

- Multiple CAN Channels: Supports multiple channels of CAN, extended CAN, CAN FD, and ISO15765.

- Additional Supported Protocols: LIN 1.X, 2.X, J2602, SAE J1939, and SAE J1850.

- Custom Protocols: TSL is adaptable to support some custom protocols.

Customized testers engineered to meet your specifications

Test systems can be tailored to meet your needs, with support for serial, parallel, USB, and Ethernet communications for input and output devices such as barcode scanners, printers, and networking. They can utilize ODBC, RUMBA, and TCP port client-server connections for data transfer and logging. If your product testing requires it, the tester can support an internal Digital Multimeter (DMM), allowing for various types of testing such as resistance, voltage, capacitance, inductance, frequency, and time measurements. This can also include a source meter and a switching card specifically made for AirBag testing.

Our testing products